Galvanized Steel vs. Galvannealed Steel: A Comparative Analysis of Coatings and Applications

In the realm of steel manufacturing, two commonly used variations of steel coatings are galvanized steel and galvannealed steel. While both offer protection against rust and have a range of industrial applications, they possess distinct characteristics that set them apart. Understanding the differences between galvanized steel and galvannealed steel is essential for making informed decisions in various construction, automotive, and manufacturing industries.

Galvanized Steel

Galvanized steel refers to steel that has been coated with a layer of zinc through a process called hot-dip galvanizing. This involves immersing the steel in a bath of molten zinc, forming a metallurgical bond between the zinc and the steel surface. The zinc coating acts as a sacrificial barrier, providing cathodic protection to the underlying steel. This means that even if the zinc coating gets scratched or damaged, the exposed steel is still protected due to the galvanic nature of the zinc. Galvanized steel offers excellent corrosion resistance due to the self-healing property of the zinc layer, which can naturally repair minor damages and scratches over time.

One of the reasons for the effectiveness of galvanized steel in preventing corrosion is the formation of a protective layer of zinc oxide and zinc carbonate on its surface. These compounds act as a barrier, shielding the steel from corrosive elements such as moisture and oxygen. Galvanized steel is commonly used in outdoor applications where it is exposed to harsh environmental conditions, including construction, infrastructure, and automotive industries. It provides durability, long service life, and requires minimal maintenance throughout its lifespan.

Galvannealed Steel

Galvannealed steel is a specialized form of galvanized steel that undergoes an additional manufacturing step known as annealing. After the steel is galvanized, it is heated to a high temperature, typically in a controlled atmosphere, allowing the zinc coating to react with the iron in the steel. This results in the formation of a zinc-iron alloy layer on the surface of the steel. The alloyed coating provides unique characteristics to galvannealed steel, making it suitable for specific applications.

One significant advantage of galvannealed steel is its superior paint adhesion compared to galvanized steel. The alloyed coating creates a rougher surface texture, which enhances the mechanical bond between the steel and the paint. This results in improved paint durability, reduced paint peeling or chipping, and increased resistance to abrasion. Galvannealed steel is often used in industries that require high-quality paint finishes, such as automotive body panels, appliances, and HVAC systems.

Furthermore, galvannealed steel exhibits excellent weldability. The alloyed coating promotes better fusion between the steel and the welding material, resulting in strong and reliable weld joints. This is particularly advantageous in the automotive and manufacturing sectors, where welding is a common fabrication process.

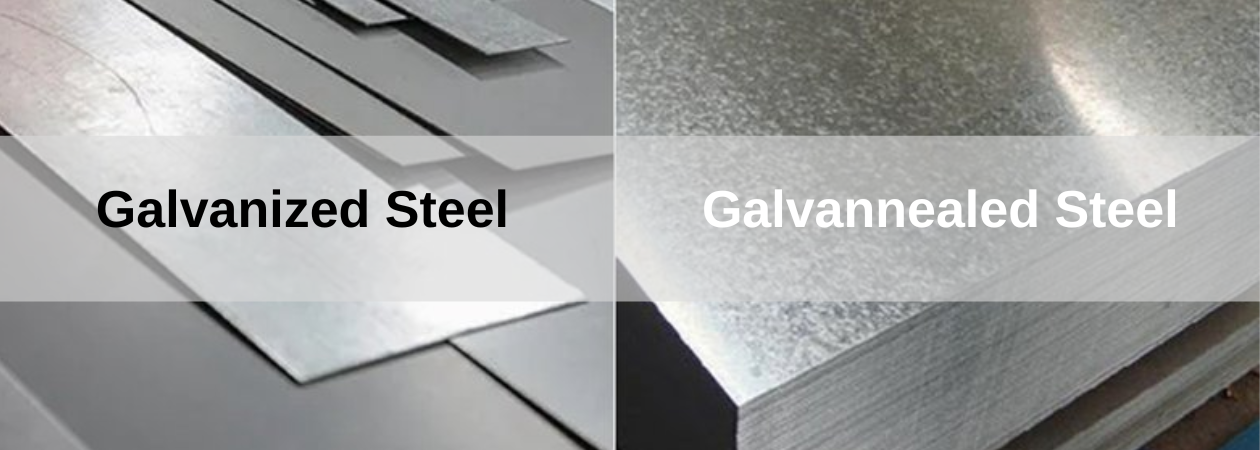

In terms of appearance, galvanized steel has a shiny, metallic surface, while galvannealed steel has a matte, gray finish. The difference in appearance is due to the presence of the alloyed coating in galvannealed steel, which alters the reflectivity of light.

It is worth noting that both galvanized steel and galvannealed steel offer excellent corrosion resistance. The zinc coating in both cases acts as a protective barrier, preventing direct contact between the steel and corrosive elements. The alloyed coating in galvannealed steel further enhances its corrosion resistance, making it suitable for environments where additional protection is required.

Galvanized Steel vs. Galvannealed Steel

Let's compare the key properties of galvanized steel and galvannealed steel.

|

Properties |

Galvanized Steel |

Galvannealed Steel |

|

Coating Composition |

Pure Zinc |

Zinc-Iron Alloy |

|

Appearance |

Shiny, Metallic |

Matte, Gray |

|

Paint Adhesion |

Good |

Excellent |

|

Weldability |

Good |

Excellent |

|

Corrosion Resistance |

Excellent |

Excellent |

|

Formability |

Good |

Good |

|

Surface Finish |

Smooth |

Matte, Rough |

|

Edge Protection |

Standard |

Enhanced |

|

Self-Healing |

Yes |

No |

Galvanized steel and galvannealed steel are two widely used steel coatings with unique properties and applications. Galvanized steel excels in outdoor environments, providing excellent corrosion resistance, durability, and self-healing capabilities. It is commonly employed in construction, infrastructure, and automotive industries. Galvannealed steel finds its niche in applications that demand superior paint adhesion and weldability, such as automotive body panels and appliances. Its alloyed coating provides enhanced paint finishes and mechanical bond strength. By understanding the distinctive attributes of galvanized steel and galvannealed steel, stakeholders in the construction, automotive, and manufacturing sectors can make informed decisions when selecting the appropriate steel coating for their specific requirements.

- Smart Vietnam: PickupPack – The Mobile Storage Master

- Smart Vietnam: Aluminum Truck Racks – The Reliable Workhorse

- Smart Vietnam: Heavy-Duty Ute Tipper – Work Smarter, Not Harder

- Smart Vietnam: Motorcycle Loader – For Safe, Easy Transport

- Smart Vietnam: One Tonne Tilt Tray Ute – Simplify Your Heavy Lifting

- Smart Vietnam: 183cm Metal Garage Storage Cabinet with Handles and Wheels

- Smart Vietnam’s Strategic Vision: Market Diversification and Mechanical Innovation

- Smart Vietnam Leads the Charge in Enhancing Vietnam’s Manufacturing Competitiveness

- Smart Vietnam's 19 in Wall-Mount 12U Sheet Steel Cabinet: Tough, Functional, and Built to Last

_cr_334x118.png)

-min_cr_334x118.jpg)